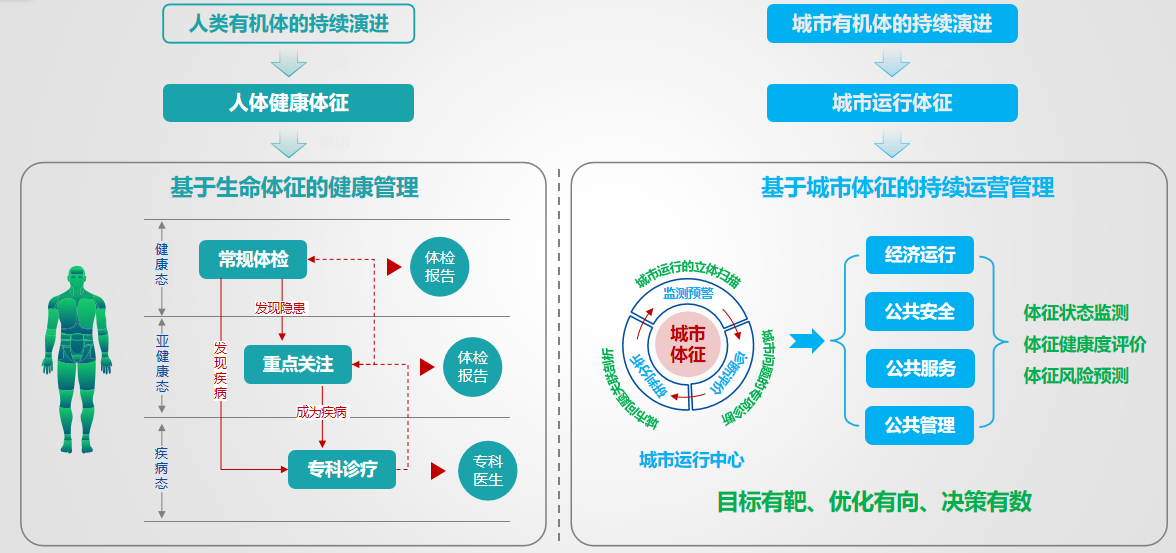

Driven by the strategic "Artificial Intelligence+" initiative, the energy and chemical industry is entering a critical window for digital transformation. Traditional management models in energy and chemical groups face issues such as lack of visualization and decision support tools, varying degrees of integration across sectors, and data silos between systems, constraining the development of new quality productive forces and operational efficiency gains.

Sefon Software, with deep insight into industry pain points, has constructed an Industrial Collaborative Management Platform for energy and chemical groups. Covering sectors like coal power, coal chemicals, new energy, construction engineering, and investment, it meets application service needs including industry supervision, collaborative scheduling, decision support, and business analysis, driving the deep integration of collaborative management and digital transformation in the energy and chemical industry.

Core Application Scenarios

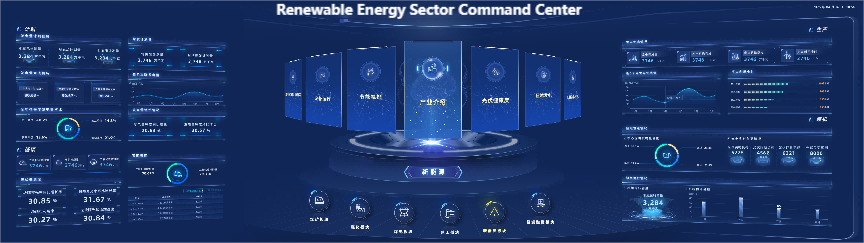

- Business Analysis IOC Theme

Utilizing visualization technology, it panoramically displays core production and operation indicators across industry sectors, focusing on key metrics like "One Profit & Five Ratios". It enables cross-domain benchmarking, achieves financial-to-operational drill-down, identifies business gaps, and supports refined management decision-making.

- New Energy IOC Theme

Centered on equipment operation, emission reduction, etc., it establishes four systems: planning, production, low-carbon, and installed capacity. Tracks power generation plans, unit operating capacity, and related emission reduction indicators, promoting green energy development.

- Construction Engineering IOC Theme

Centered on project cost, materials management, etc., it constructs four key indicators: planning, cost, construction progress, and materials management. Monitors plan achievement rate, project direct costs, and materials procurement/storage costs, enhancing project management capabilities.

Centered on project cost, materials management, etc., it constructs four key indicators: planning, cost, construction progress, and materials management. Monitors plan achievement rate, project direct costs, and materials procurement/storage costs, enhancing project management capabilities.

Business Data Collection & Governance

Supports the collection and aggregation of massive, cross-domain, heterogeneous data. Builds capabilities for data adaptation, access, acquisition, transmission, and exchange covering all data sources across the entire group, providing data acquisition support for the data middle platform.

System Function Construction

Coal Mining Production Management System: Integrates remote mine centralized control, safety monitoring (gas/dust), resource scheduling, and production capacity planning monitoring.

Coal Chemical Production Control System: Manages chemical production lines (synthetic ammonia/urea/methanol), real-time monitoring of process parameters like reactor vessel temperature, pressure, air-fuel ratio.

Power & New Energy Monitoring System: Monitors thermal power unit operation, photovoltaic power generation efficiency, green hydrogen production, and carbon emissions.

Construction Project Management System: Covers engineering budgeting, progress tracking, material procurement, cost allocation, supporting full-cycle EPC (Engineering, Procurement, Construction) contract management.

Supply Chain Management Platform: Integrates procurement planning, supplier evaluation, logistics tracking, and cross-enterprise inventory collaboration.

Intelligent Procurement System: Automates supplier screening, demand forecasting, contract signing, and cost analysis.

Sales Management System: Manages customer orders, pricing strategies, logistics tracking, accounts receivable, supporting multi-terminal order creation.

Inventory Management System: Real-time monitoring of multi-warehouse inventory, intelligent replenishment alerts, transfer optimization, and cost accounting.

Four-Level Repository Construction:

- Raw Repository:

Directly extracts raw data from business systems, preserving full-volume, unprocessed real-time and historical data streams.

Main System Data Examples:

Coal Mining Production Management System: Mine geological radar data, shearer real-time position/attitude, gas concentration second-level time-series data, raw waveforms of equipment current/voltage.

Coal Chemical Production Control System: Raw sampling values of reactor vessel temperature/pressure, catalyst activity curves, DCS control command streams.

Safety Monitoring & Emergency System: Underground personnel location tracks, infrared thermal imaging, equipment overheating alarm logs.

Power & New Energy Monitoring System: Raw records of thermal unit coal consumption, photovoltaic panel output current fluctuation data, green hydrogen electrolyzer voltage curves.

Transportation Dispatch System: Vehicle GPS point streams, driver facial recognition videos, load sensor real-time data.

Inventory Management System: Raw warehouse temperature/humidity sensor data, PDA barcode scan records, inventory dynamic transaction logs.

Equipment Maintenance Management System: Raw equipment vibration spectrum waveforms, uncalibrated oil composition test data, AR disassembly guidance video streams.

Energy & Carbon Management System: Raw pulse data from electricity/water meters, uncalibrated carbon emission factor data, green power consumption certificate records.

- Standard Repository:

Cleanses, transforms, and standardizes raw data. Builds enterprise-level master data and data quality rules, unifying material codes, equipment IDs, unit conversions, safety threshold definitions, etc.

Standardization Content:

Equipment Master Data: Unified coding rules (e.g., Reactor ID = Plant Code + Production Line Code + Equipment Type).

Coal Chemical Production Control System: Coal calorific value grading standards (e.g., 5500 kcal thermal coal), binding CAS numbers for chemical raw materials.

Safety Threshold Rules: Gas concentration >1% invalid, air-fuel ratio valid range (0.95-1.05), non-negative inventory quantity constraint.

Unit Standardization: Pressure unified to MPa, energy consumption unified to tons of standard coal equivalent, carbon emissions converted to CO₂ equivalent.

Spatial Data Specifications: Mine coordinate system unified to CGCS2000, tank volumes linked to GIS maps.

Supplier Master Data: Supplier credit rating rules (A/B/C levels), logistics carrier qualification classification standards.

Data Desensitization Rules: Personnel location data hides names, transport trajectories encrypted storage, financial data access tiering.

- Subject Repository:

Integrates data by business domain, fusing related system data to form cross-system subject models.

Subject Repository Data Content:

Production Safety Monitoring Subject: Equipment basic info (Std Repo) + real-time vibration data (Raw Repo) + maintenance records (Eqpt Sys) + energy efficiency indicators (Energy Sys).

Energy Flow Analysis Subject: Coal consumption (Prod Sys) + power generation (Power Sys) + green hydrogen output (NE Sys) + carbon footprint (Carbon Sys).

Production Safety Subject: Geological structure data (Mining Sys) + gas concentration (Safety Sys) + emergency plans (Constr Sys).

Supply Chain Subject: Procurement demand (Proc Sys) + supplier ratings (SCM Platform) + inventory dynamics (Inv Sys) + logistics timeliness (Trans Sys).

Cost & Profit Subject: Raw material cost (Fin Sys) + energy cost (Energy Sys) + sales gross profit (Sales Sys).

Project Control Subject: Engineering budget (Constr Sys) + progress milestones (Eqpt Sys) + cash flow (Fin Sys).

Carbon-Energy Synergy Subject: Green power consumption (NE Sys) + grid peak-shaving revenue (Energy Sys) + carbon quota trading data (Carbon Sys).

Emergency Command Subject: Risk alerts (Safety Sys) + personnel distribution (Mining Sys) + rescue resources (Inv Sys) + traffic conditions (Trans Sys).

- Scenario Repository:

Deeply aggregates data for specific scenarios, supporting analytical applications (e.g., predictive maintenance, carbon footprint tracing).

Scenario Repository Construction Content:

Business Overview Scenario: Production capacity overview, production completion rate, total profit, core business indicators (One Profit & Five Ratios), asset scale, tax paid, investment plan completion rate.

Coal Mining Sector Scenario: Production/sales trends, supply guarantee achievement rate, inventory turnover days, safety incident count, environmental compliance rate, equipment utilization rate, cost composition analysis.

Coal Chemical Sector Scenario: Capacity plan execution rate, inventory cost proportion, regional sales ranking, chemical product sales heatmap, inventory turnover optimization suggestions.

Coal Power Sector Scenario: Coal-fired unit installed capacity, power supply standard coal consumption curve, power generation completion rate, sulfur dioxide emission monitoring, unit real-time load heatmap.

New Energy Sector Scenario: PV equipment health score, power generation growth rate, CO₂ reduction volume, unit operating capacity utilization rate, safety monitoring alerts.

Construction Engineering Sector Scenario: Engineering cost structure (labor/material/equipment), material procurement cycle analysis, construction progress Gantt chart, plan achievement rate comparison.

Investment & Financing Sector Scenario: Investment/financing project return radar chart, risk level assessment matrix, industry-finance synergy revenue proportion, performance KPI achievement heatmap.

Comprehensive Display on Large, Medium & Small Screens

Visualization Construction

Centered closely on business scenarios like chemicals, coal power, new energy, construction engineering, and investment/financing, and combined with specific user needs, it builds data indicator systems. With "Comprehensive Application on Large, Medium & Small Screens" as the core, it creates multi-dimensional data insight capabilities covering decision-making, management, and execution layers.

Comprehensive Application on Large, Medium & Small Screens:

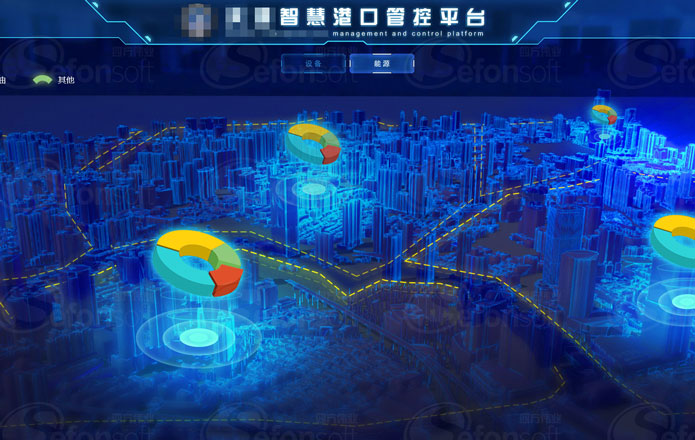

- "One-Map" Large Screen:

Data-driven, constructs core business scenarios, displays global indicator data, helping decision-makers grasp the overall situation efficiently, objectively, and comprehensively.

- "One-Map" Medium Screen:

Decision-need oriented, supports instruction issuance, integrates monitoring, alerting, analysis, and command, assisting decision-makers in mastering key data they care about.

- "One-Map" Small Screen:

Aims for efficient collaboration, breaks time and space constraints, enables convenient data browsing via mobile phones, tablets, and other terminals, achieving efficient collaboration and instant response.

AI-Driven Intelligent Analysis

Smart Data Query

Sefon Software, through the SDC GDE Smart Data Query & Analysis Platform, leverages AI and large model algorithms to provide proactive response and intelligent analysis decision-making capabilities. Covering core sectors like production, construction, and investment/financing, it extracts targeted and in-depth questions around key indicators and business processes. Enables transformation of data indicators from manual lookup to intelligent push and intelligent generation.

- Intelligent Q&A (Knowledge):

Provides domain experts in energy & chemical planning, production safety, quality inspection processes, equipment maintenance, etc., with specialized knowledge bases on design standards, process flows, etc.

- Intelligent Data Query:

For managers and operational staff, automatically generates relevant data through a "query-and-get-answer" interface, visualized via charts.

- Intelligent Reporting:

Applied to drafting various analysis reports (e.g., fuel, energy consumption), feasibility studies, etc. Rapidly generates materials and charts using large models to complete report editing, improving office efficiency.

- Intelligent Perception:

Based on user profiles and business hotspots, intelligently recommends indicator cards. Shifts from passive lookup to active perception, focusing on variable business and solving information overload.

Based on cutting-edge big data and AI technologies, Sefon Software has constructed a comprehensive digital management platform for energy and chemical groups, forming a closed-loop management system of "Monitoring - Analysis - Scheduling - Feedback". By deeply developing data elements, it promotes efficient collaboration across the energy and chemical industry chain, achieving optimized resource allocation and enhanced operational efficiency, providing a new growth engine for China's energy and chemical industry.

Copyright ©Chengdu Sefon Software Co.,Ltd.

蜀ICP备14024109号

Copyright ©Chengdu Sefon Software Co.,Ltd.

蜀ICP备14024109号