Digital Transformation of Manufacturing Enterprises

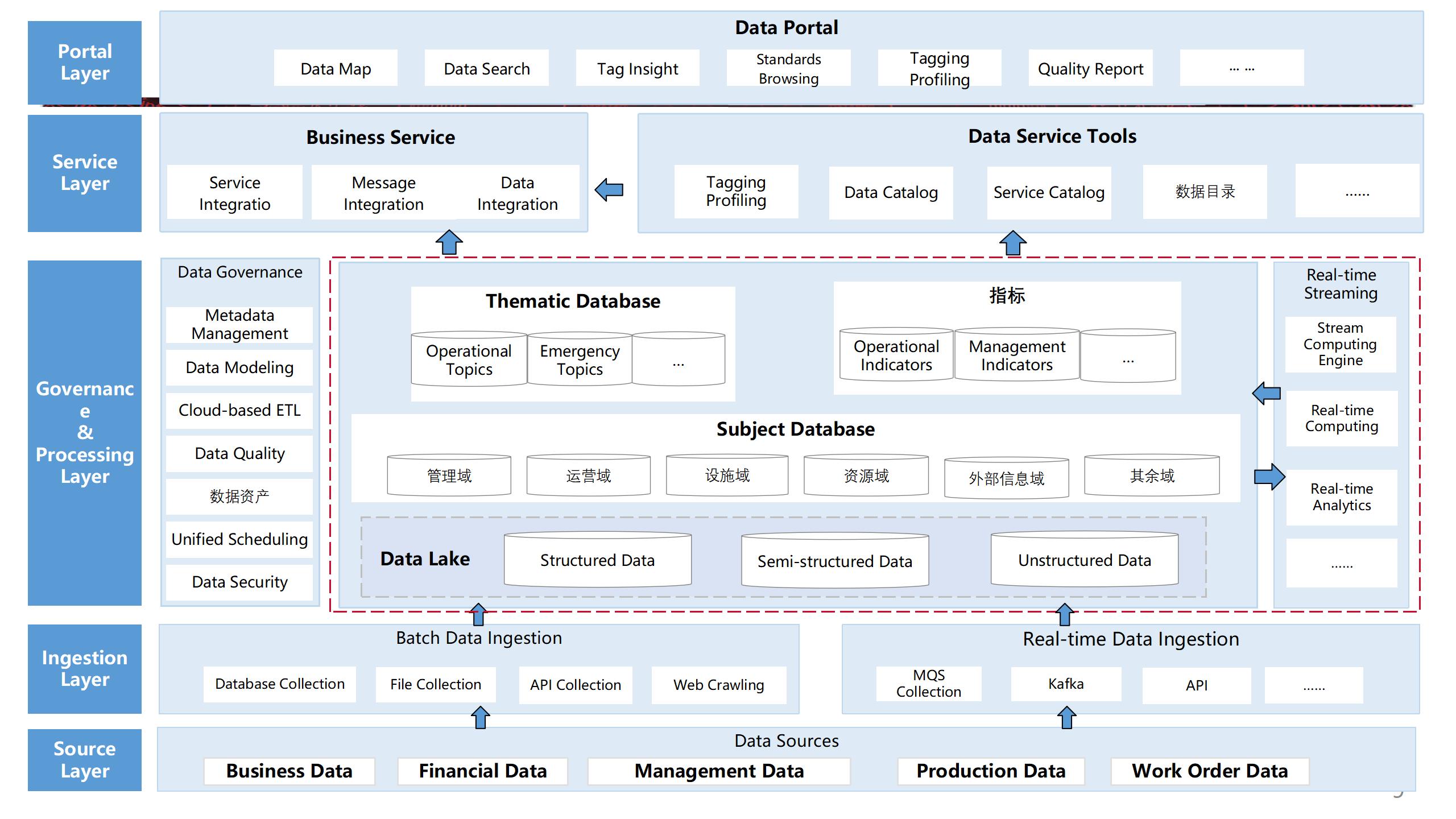

Facing the global industrial chain restructuring under digital transformation, traditional manufacturing, which relies on manual labor and extensive management, struggles to integrate into the modern ecosystem. With the maturity of technologies such as big data, artificial intelligence, and digital twins, digital transformation has expanded from isolated applications to full-chain reconstruction

Copyright ©Chengdu Sefon Software Co.,Ltd.

蜀ICP备14024109号

Copyright ©Chengdu Sefon Software Co.,Ltd.

蜀ICP备14024109号